Brand : TRLON

Product origin : CHINA

Delivery time : 50 days

Supply capacity : 1 Million tons of water

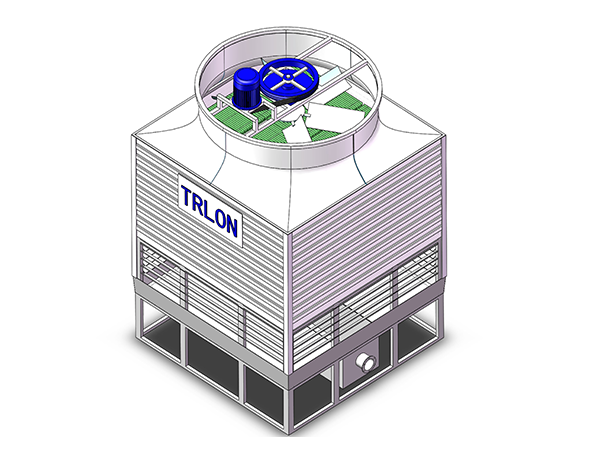

TCH series of square cross-flow cooling towers, the main frame adopts channel steel as the main frame, and is equipped with other structural parts to ensure sufficient rigidity and strength of the overall structure. The side panels of the cooling tower are made of smooth glass fiber reinforced plastic protective panels, and the heat insulation layer is spread in the side panels to prevent external heat from entering the tower, and the effect of heat insulation and shock absorption is excellent. Modular rib design, good strength, rigidity, beautiful appearance, flexible and convenient assembly; the bottom basin is assembled with thickened glass fiber reinforced plastic, and waterproof rubber pads are installed between the bottom plates, which does not leak water, has good sealing performance and long service life. FRP material, acid and alkali resistance, effectively eliminate the shortcomings of easy oxidation and black surface.

1、Desined with a more robust tower structure,make the cooling tower more durable.

2、Deepened the depth of the water collecting basin to prevent water leakage and drain.

3、Equipped with optional intelligent electrical control cabinets.

4、Desined larger tower body so area of filling is larger, which means better heat dissipation performance.

5、Fillings with patent, better on heat dissipation

6、Rich models of the nozzles are used in TCH.

7、Positive triangle arrangement designed for the nozzles. According to the hydraulic characteristics of different nozzles, combined with the actual operating level change of the basin, the spacing and number of the nozzles are reasonably optimized to ensure uniform water distribution and full heat exchangere of the fillers.

8、More accurate testing and more model choices allow customers to choose the one they need most without worrying about thermal performance.

9、Noise control measures with test and simulation,create a more quiete enviroment.

10、Drive System provide variable options on Motors and more durable with accurate reducer,anti-skid belt, imported NSK bearing.

Excellent Anti-drift Desin. Drive System provide variable options on Motors and more durable with accurate reducer,anti-skid belt, imported NSK bearing.

Introduction to Configuration

Hollow Type Axial Fan

Airfoil-shaped hollow blade fans are made from Aluminum extrusion alloy. Fan hubs are fabricated from hot-dip galvanized (HDG) circular plate with epoxy coated cast iron core and Aluminum blade camps. The fan blades are adjustable in pitch to allow for maximum utilization of rated horsepower and optimum performance. High efficient lower tip speed and light weight design ensure low power consumption and low noise level, thus and guarantee 100% performance.

Transmission System

The fan motors are TEFC type with IP55 weather proof, Class E insulation. Fans are driven by vee belt and the speed can be adjusted by changing pulleys to meet different requirement. By locating the motor on top of fan stacks, the vee belt lengths are shorthen thus ensure linger belt life. Motor mounted in the outside air stream and with gear driven system are also available upon request.

Distribution System

Open gravity fed water distribution basins with removable cover are made of FRP

You can choose 304 stainless steel or galvanized steel) and are designed for non-clogging operation and ease of inspection. Special design diffusion decks are placed on top of filler as a re-distribution layer to ensure full coverage of filler.

High Efficient Filler

Fillers are vacuum formed of 0.4mm (1/64”) thick PVC film. Filler sheets configuration incorporates sloped flutes in both air intake and outlet sections and are high efficient wet deck media. The honeycomb shaped air intake louver section contributes minimum resistance to airflow and prevents ingress of foreign matters. The sloped flutes in the outlet section of filler sheets act as the primary drift eliminators to reduce droplets escaping through the exhaust air stream. Primary drift eliminat or ensures drift loss less than 0.005% of circulating water flow. The wet deck media with continuous triangular pattern is specially designed to provide maximum air/water contact and lower resistance ensuring high efficient heat transfer.

Casing Panels and Cold Water Basin

Casing, basins and fan stacks are made of FRP. The smooth and attractive gel-coat is applied on exterior surface for UV protection, chemical resistance and long life. It is light in weight and makes easier for assembly and transportation. Hot-dip galvanized (HDG) or all Stainless Steel (SS304 or SS316) casing and basins instead of FRP are also available.

Sump Tank

FRP cold water sump tanks contain all connection fittings and make inspection or maintenance of fittings easier. Depressed sump tanks provide basin depth and less chance of pump cavitation.

Steel Structure

All supporting steel members are hot-dip galvanized (HDG) to minimize rust forming and corrosion , ensuring long service life. Stainless steel (SS304 or SS316) hardware members are also available upon request.

Inspection Door

Inspection door is furnished to provide convenient access to the interior for inspection, maintenance, adjustment of float valve, cleaning of the lift-out strainer and flushing of the basin

Article Address:https://www.trlen.com/product/4.html

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen