The cooling tower body is an anti-seismic structure, and the specifications, models, and thickness of the structural steel should comply with the relevant standards. All parts should be surface treated with hot-dip galvanizing, and the connecting fasteners should be stainless steel. So what parameters do you need to know when choosing a cooling tower? The following closed cooling tower manufacturer Guangdong Teling Air Conditioning Belt will take you to learn more!

1. The specific parameters of the cooling tower design are subject to the air-conditioning host parameter requirements in the design drawings (excluding the control cabinet).

2. Must consider the inlet and outlet water temperature specified in the design plan, the hourly chilled water flow rate under the humidity standard, and the index value of ultra-low noise. Be sure to show the manufacturer's calibrated machine equipment model, specifications, characteristic index values, appearance specifications, manual and operating net weights, noise index values and other materials.

3. The manufacturing of cooling towers must meet the requirements of the GB/T7190.1-2008 standard, and the main technical requirements are as follows:

(1) The cooling capacity is not less than 95.0%.

It is estimated that the power consumption ratio does not exceed 0.035 kilowatts/(cubic meters/hour).

The bleaching rate shall not exceed 0.015% of the nominal cooling water output.

(4) The noise level is ultra-low noise category C, the noise index of the cooling tower with a nominal cooling water output of 125 m3/h does not exceed 58.0dB(A), and the noise index of the cooling tower with a nominal cooling water flow of 250 m3/h does not exceed 60.5dB(A). What parameters should be understood when choosing a cooling tower?

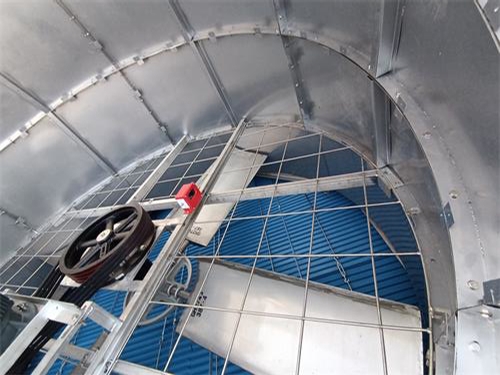

4. Cooling tower body.

(1) The FRP cooling tower is of seismic grade structure, stainless steel plate specifications, model specifications, thin and thick, should meet the requirements of relevant regulations. All parts shall be treated with hot-dip galvanized metal surface treatment, and stainless steel plates shall be used for connecting standard parts.

The flexural rigidity of the tower conforms to the relevant standards, and the 7-degree seismic fortification intensity of the area should be considered, and its wind resistance should reach 250 kg/m2 or more.

5. Cooling tower glass fiber reinforced plastic parts.

(1) Use corrosion-resistant, weather-resistant, impact-resistant glass fiber elastomer material (FRP), and no impurities such as light calcium powder are allowed; the surface layer should be imported latex coating with good aging resistance and reliability, and the thickness should be controlled within Within the range of 0.3-0.0 mm; the raw materials used should meet the requirements of relevant specifications, and the index values of epoxy resin composition, dryness, bending strength, Balmer's hardness, etc. should be fully considered in accordance with the requirements of the national standard for glass fiber reinforced plastic cooling towers; It is stipulated to use flame-retardant epoxy resin, and its flame-retardant grade inspection standard value is 28. Other raw materials selected for the tower surface should also be flame-retardant materials.

FRP anticorrosive The outer latex coating should be uniform, and the surface layer should be smooth, without cracks, and uniform in color. There should be no more than 3 bubbles with a diameter of 3-mm in the outer surface layer 1 of the tower body, and bubbles with a diameter greater than mm are not allowed to appear. The surface layer of the lower tower body should be rich in resin, and the epoxy resin content should be more than 70%. The edge of the tower body should be neat, uniform in thickness, without delamination, and the cutting section should be sealed with resin.

6. Cooling tower fan.

(1) The technical parameters of the centrifugal fan should conform to the working conditions of the design scheme. Before the centrifugal fan is assembled, a balance experiment should be carried out, and the blades should be accurately positioned and serial number after balancing.

The applicable motor and reducer are the same as the centrifugal fan. The motor is a fully enclosed outdoor type, with a flame-retardant grade above b and a waterproof grade of 1P55. The famous brand and manufacturer should be indicated, and the place of origin should be indicated for imported motors.

Reducers, shafts, bearings, belts, and pulleys are required to be high-quality parts, and the product brand, specification, model, material, and manufacturer are marked, and imported parts are marked with the place of origin.

The specified compressive strength of centrifugal fan blades depends on,, the surface is smooth, the cross-sections are excessively symmetrical, there are no defects such as cracks, vacancies, burrs, etc.; from the surface of the glass fiber reinforced plastic fan blade, it can be seen that the bubble diameter is not more than 2mm, every 100 The number of bubbles in the area of mm is not more than 3.

The gap between the blade and the inner cavity of the fan should be symmetrical, and its value should not exceed 0.008 times the diameter of the centrifugal fan.

[6] The rotary bearing of the centrifugal fan should adopt a built-in dripping structure for easy maintenance; a reliable safety net should be set above the centrifugal fan to prevent dirt from entering the glass fiber reinforced plastic cooling tower.

7. Cooling tower packing.

(1) Cooling tower accessories should be made of materials with high cooling efficiency, low friction resistance of natural ventilation, and fireproof materials; the use of recycled materials or partially recycled materials is prohibited. What basic work should be done before cooling tower filling operation?

When the filler is installed, it is specified that the gap is symmetrical, the top of the wall is level, and there is no slump or delamination. It can withstand 2.94KN per square meter, and the filler cannot be worn.

The above is about "What parameters do you need to know about cooling tower selection?" I hope this article can be helpful to everyone. If you want to know more about it, you can continue to follow us.

Article Address:https://www.trlen.com/news/552.html

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen